RUAG Aviation announces the successful conclusion of their first heavy maintenance event for a Dassault Falcon 7X. The Dassault Falcon 7X C-check was one of three concurrent C-check events at the Dassault Falcon Authorized Service Centre in Geneva which also included two Dassault Falcon 2000 for 3C- and 2C-checks, respectively. The owner of the Dassault Falcon 7X took timely delivery of the aircraft in an official celebration of this milestone.

The triple heavy maintenance project at RUAG Aviation in Geneva, begun in February 2017, has concluded with the successful delivery of the facility’s first Dassault Falcon 7X.

“This is a milestone for us and we are proud of our team’s performance. Our personnel proved their professionalism and their dedication to quality service, as they approached this first-ever Falcon 7X project with precision planning and coordinated technical operations. Customer satisfaction was high, as the inspection progressed according to plan, remained within budget, and ensured on-time aircraft availability,” clarified David Ricklin, General Manager Site Geneva, RUAG Aviation.

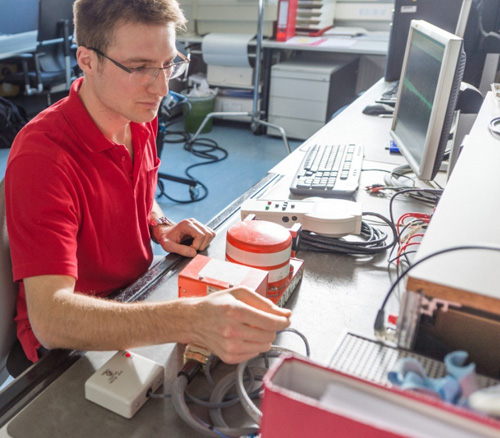

The heavy maintenance event posed fresh challenges for the RUAG team. This first Dassault Falcon 7X C-check inspection ran concurrently with two C-checks for two Dassault Falcon 2000. New processes were defined, new SAP workflows were triggered, and contractors were integrated within the existing team of RUAG specialists. These variables, and several others, combined in the operational environment for the first time. Project success required increased discipline and focus from the entire organization, from maintenance and operations management, to the technicians and support specialists on the shop floor. Together, the three maintenance events totaled over 19’000 hours with the team opting for double-shifts to accommodate the breadth of work and guarantee on-time delivery.

"Our people, our facility, and our processes functioned as a whole, demonstrating flexibility, responsiveness, and outstanding teamwork on behalf of the customers and their aircraft. Our customers count on our complete project transparency and on-time delivery, while we rely on our entire team for the skilled efficiency and safe practices necessary to fulfill these expectations,” explained Stéphane Ruh, Maintenance Manager, RUAG Aviation.

David Ricklin also credits the continuing partnership between Dassault and RUAG Aviation as a determining factor in the success of this first Falcon 7X project. “Our colleagues from Dassault provided us with excellent collaboration and valuable support, allowing us to respond promptly to our customer’s needs,” he states.

RUAG Aviation is a leading supplier, support provider and integrator of systems and components for civil and military aviation worldwide.

Servicing aircraft and helicopters throughout their entire life cycle, the company’s core competencies include maintenance, repair and overhaul services, upgrades, and the development, manufacturing and integration of subsystems.

RUAG is an authorized service center for OEMs of renown, such as Airbus Helicopters, Bell, Bombardier, Cirrus, Cessna, Diamond, Dassault Aviation, Embraer, Leonardo, Piaggio, Sikorsky, Piper, and Mooney, as well as a service center for 328 Support Services, Hawker Beechcraft, Viking und MD Helicopters. RUAG Aviation is also a partner to the Swiss Armed Forces and other international air forces.

The company is also the manufacturer (OEM) of the Dornier 228, a versatile aircraft for special missions, as well as passenger and cargo operations.

RUAG Aviation is an approved Part 21/J EASA Design Organization, Part 21/G EASA Production Organization, and Part 145 EASA Maintenance Organization.