FN Herstal’s Use of Advanced Composite Material

09.07.2013 Europe

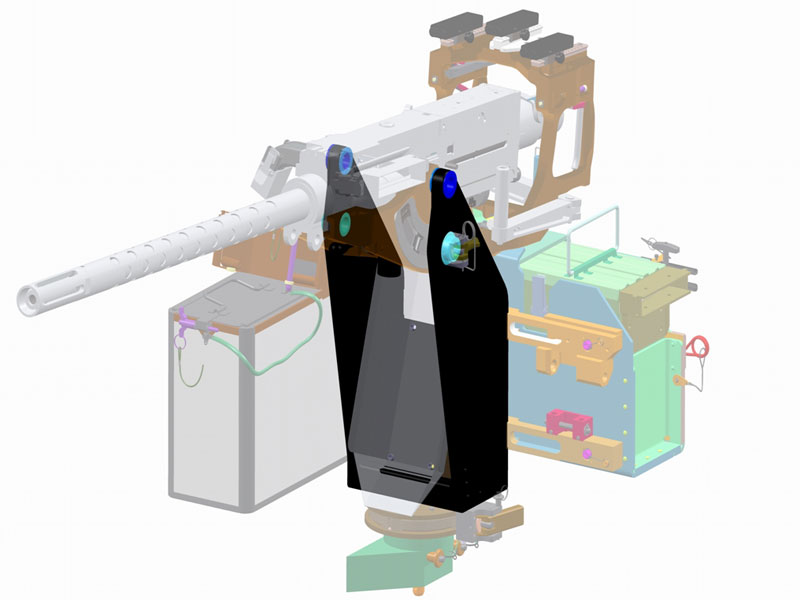

For the first time in its history, Belgium based FN Herstal has utilized advanced composite material for yoke manufacturing.

The yoke is a critical and complex mechanical component on the FN Medium Door Pintle Turning (FN MDP™ Turning). It is exposed to helicopter vibrations and firing recoil forces of the weapon, and is designed to sustain 20g crash loads as per the existing standards.

By using the advanced composite material the weight of the yoke is reduced by 30% decreasing the overall weight of the pintle weapon system - a critical aspect in aeronautics - while maintaining all structural properties of the previous aluminum version.

By integrating advanced technologies and materials in airborne weapon systems, FN Herstal further strengthens its position as a leading solution provider for MODs and OEMs.

The prototype of the newly developed yoke is on display at the FN Herstal booth during the ongoing Paris Air Show (Le Bourget; 17-23 June 2013).

Since its creation in 1889, FN HERSTAL has designed, developed and manufactured small caliber firearms and products based on state-of-the art technologies, imposing itself over the decades as a leading supplier of light and portable weapons, integrated weapon systems and ammunition to military, law enforcement and special forces operators worldwide.

The recent years were no different with FN Herstal launching a number of newly developed products, such as the FN SCARR family including a 5.56 or 7.62 assault rifle, a 40mm grenade launcher and a precision rifle, the FN FCU™ Fire Control Unit for 40mm grenades, the FN MINIMIR 7.62 machine gun, and the FN SmartCoreR shot counter. On the integrated weapon systems, the development of a deFNderR RWS line was undoubtedly a significant step.

The yoke is a critical and complex mechanical component on the FN Medium Door Pintle Turning (FN MDP™ Turning). It is exposed to helicopter vibrations and firing recoil forces of the weapon, and is designed to sustain 20g crash loads as per the existing standards.

By using the advanced composite material the weight of the yoke is reduced by 30% decreasing the overall weight of the pintle weapon system - a critical aspect in aeronautics - while maintaining all structural properties of the previous aluminum version.

By integrating advanced technologies and materials in airborne weapon systems, FN Herstal further strengthens its position as a leading solution provider for MODs and OEMs.

The prototype of the newly developed yoke is on display at the FN Herstal booth during the ongoing Paris Air Show (Le Bourget; 17-23 June 2013).

Since its creation in 1889, FN HERSTAL has designed, developed and manufactured small caliber firearms and products based on state-of-the art technologies, imposing itself over the decades as a leading supplier of light and portable weapons, integrated weapon systems and ammunition to military, law enforcement and special forces operators worldwide.

The recent years were no different with FN Herstal launching a number of newly developed products, such as the FN SCARR family including a 5.56 or 7.62 assault rifle, a 40mm grenade launcher and a precision rifle, the FN FCU™ Fire Control Unit for 40mm grenades, the FN MINIMIR 7.62 machine gun, and the FN SmartCoreR shot counter. On the integrated weapon systems, the development of a deFNderR RWS line was undoubtedly a significant step.

Previous PostDSEI 2013: Venue for Cross Sector Capabilities

Latest news

Latest events

Doha International Maritime Defence Exhibition & Conference (DIMDEX 2026)

19 - 22 Jan 2026Doha - QatarUMEX – SimTEX

20 - 22 Jan 2026ADNEC Centre Abu Dhabi, - United Arab EmiratesWorld Defense Show (WDS) 2026

08 - 12 Feb 2026Riyadh - Saudi ArabiaSAHA EXPO International Defence & Aerospace Exhibition

05 - 09 May 2026İstanbul Expo Center - Turkey