Patriot Gets Smarter, Faster and Tougher

06.12.2012 North America

Deep inside the factory where Patriot defense systems are made, Ken Arruda stopped beside a rolling cart and pointed to a white card sprinkled with what looked like grains of sand.

They were computer chips for the Patriot's radar system – parts that since 2006 have shrunk to one-eighth their previous size.

“Now they're as small as a speck of pepper. That's how far Patriot has come in the last few years,” said Arruda, Operations Director for Raytheon's Air Defense Programs.

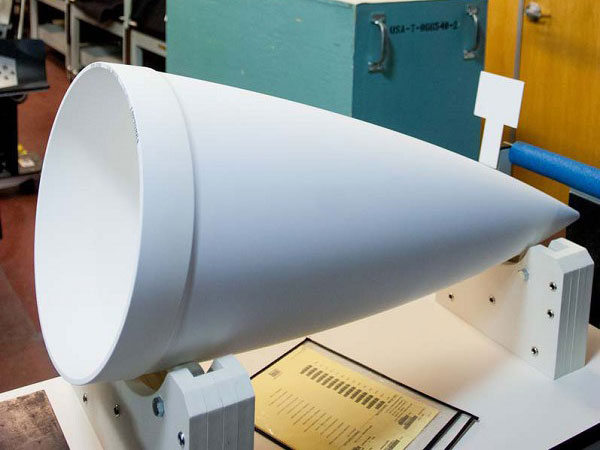

And tiny chips are just the start. From the tip of its nose cone to the base of its radar, designers have invested more than $400 million in the last four years as part of a program aimed at making the legendary air and missile defense system faster, smarter and tougher.

Miniature components have replaced racks of equipment. Touchscreens have replaced control panels. New machines in Raytheon's Andover, Mass. factory are making parts lighter, stronger and longer-lasting.

The U.S. government and other partners in the program have helped fund the modernization, but it was an order for new Patriot systems for the United Arab Emirates that gave designers the chance to reengineer Patriot from the ground up in late 2008.

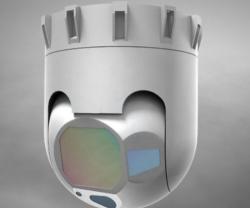

The system had already gone through several upgrades since its debut in the first Gulf War. But designers now gave the Patriot missile a faster, more accurate guidance system known as Guidance-Enhanced Missile – Tactical, or GEM-T. They rewired circuits in the radar and command stations, shrinking and speeding up components.

The missile's mobile control room got a major makeover, with huge touch screens, faster computers and sleek black keyboards replacing banks of controls.

“How we have prepared it for success in the future is really remarkable,” said Glenn Walker, a Business Development manager for Raytheon's Integrated Air and Missile Defense.

They were computer chips for the Patriot's radar system – parts that since 2006 have shrunk to one-eighth their previous size.

“Now they're as small as a speck of pepper. That's how far Patriot has come in the last few years,” said Arruda, Operations Director for Raytheon's Air Defense Programs.

And tiny chips are just the start. From the tip of its nose cone to the base of its radar, designers have invested more than $400 million in the last four years as part of a program aimed at making the legendary air and missile defense system faster, smarter and tougher.

Miniature components have replaced racks of equipment. Touchscreens have replaced control panels. New machines in Raytheon's Andover, Mass. factory are making parts lighter, stronger and longer-lasting.

The U.S. government and other partners in the program have helped fund the modernization, but it was an order for new Patriot systems for the United Arab Emirates that gave designers the chance to reengineer Patriot from the ground up in late 2008.

The system had already gone through several upgrades since its debut in the first Gulf War. But designers now gave the Patriot missile a faster, more accurate guidance system known as Guidance-Enhanced Missile – Tactical, or GEM-T. They rewired circuits in the radar and command stations, shrinking and speeding up components.

The missile's mobile control room got a major makeover, with huge touch screens, faster computers and sleek black keyboards replacing banks of controls.

“How we have prepared it for success in the future is really remarkable,” said Glenn Walker, a Business Development manager for Raytheon's Integrated Air and Missile Defense.

Latest news

Latest events

IDEF 2025 Turkey - International Defence Industry Fair

22 - 27 Jul 2025Istanbul Expo Center - TurkeyDSEI 2025

09 - 12 Sep 2025Excel, London - United KingdomIntersec Saudi Arabia

29 Sep - 01 Oct 2025Riyadh International Exhibition & Convention Centre - Saudi ArabiaDubai International Air Chiefs’ Conference (DIACC 2025)

16 Nov 2025Atlantis, The Palm Dubai - United Arab Emirates